Collecting the Facts for Preparing Process Maps

By Ben B. GrahamPresident

The Ben Graham Corporation

© Copyright 2007-2016, The Ben Graham Corporation. All rights reserved.

Links may be established to this paper.

In two previous papers, we outlined the elements involved in setting up a process improvement project and getting the word out with a public announcement. With everyone on board, it’s time to get into the trenches.

Fact gathering is an integral part of understanding reality and preparing a good process map. Yet, it is often dismissed or given cursory attention as superficial process maps are created by an individual or group of people some distance away from the work…and thereby some distance away from reality. If you want your process maps to reflect reality, you must go to the work and see it happen.

Where do we collect the facts?

Collect the facts at the work area. It has become a fairly common practice to gather the people who do the work together in a room to build a process map. While these are the right people to bring together to study and improve the process, this is not the best way to build an as-is process map. When people are away from their workplace they tend to focus on the value-added steps they perform and often overlook many of the non-value-added steps that are apparent at the workplace. Also, it wastes the time of all the other people in the room while one person is explaining their work. We use less employee time and get better results if we wait until the as-is process map is complete and then bring everyone together to study and improve it. Collect the facts at the work area. Period. Grab a clipboard and a pencil and follow the process.

Who do we interview?

Interview experienced employees. If you want to find out how a job is done, ask someone who knows how to do it. Pretty simple advice, right? Yet it is amazing how often process maps, procedures, even custom software applications are developed some distance from reality – away from the people who actually do the work.

If you want to know how a job is done, look for the person or people who

really know how to do it. You don’t want someone who has to guess their way

through the process. New hires, people who did the job years ago, people in

adjacent departments, these are wrong people and this is not a criticism of

their personal experience. They simply are not the best source of the

experience that we are seeking. You want someone who knows the work! Find the

person that the other employees go to when they are stumped. This is the

person that can show you the ropes. This is the person that can walk you

through their part of the process and answer any questions you might have.

This is the same person you will want to have on your analysis team.

In some cases, you may hear that no two people do the job the same way. There

is nothing wrong with charting a few alternative methods. Just stick with the

experienced people. You don’t have to identify every alternative method for

doing the same work. If you capture the methods of the “best” workers, you

will have a good baseline to work with.

What are we looking for?

Capture the Facts. The information that is used in our business processes and what is done with it is what we are trying to capture. That is the substance of a process. It doesn’t float around in the air. It is either in people’s heads or it is recorded on things – documents, forms, reports, email, files, records, etc. …. When information processes are mapped, it is those things (the media that are conveying the information) that are mapped. The interviewer focuses on the things that drive the process. The interviewer moves through the process from one workstation to the next, collecting copies of completed forms, source documents, screen prints, etc., that will help the team relate the process map to the actual items that flow through the process and will provide entry/field-level detail of the information that is recorded.

How do we do it?

Be genuine. Successful fact gathering requires a blend of social and technical skills. From a social standpoint, an interviewer wants to show sincere respect for the knowledge of the people who do the work and does not want to appear threatening. Assume the role of fact finder - the people are the experts. Do what you can to help employees relax and be as comfortable as they can be with someone looking over their shoulder. Collect your notes with a pencil and paper (a recorder or computer device will be more threatening) and show the person your notes, explain what you are doing, reinforce what the executive said at the kickoff meeting and show them the respect due someone who has something that you would like to learn. Make sure that employees understand what you are doing and why they are involved. They are the experts. It has to be sincere.

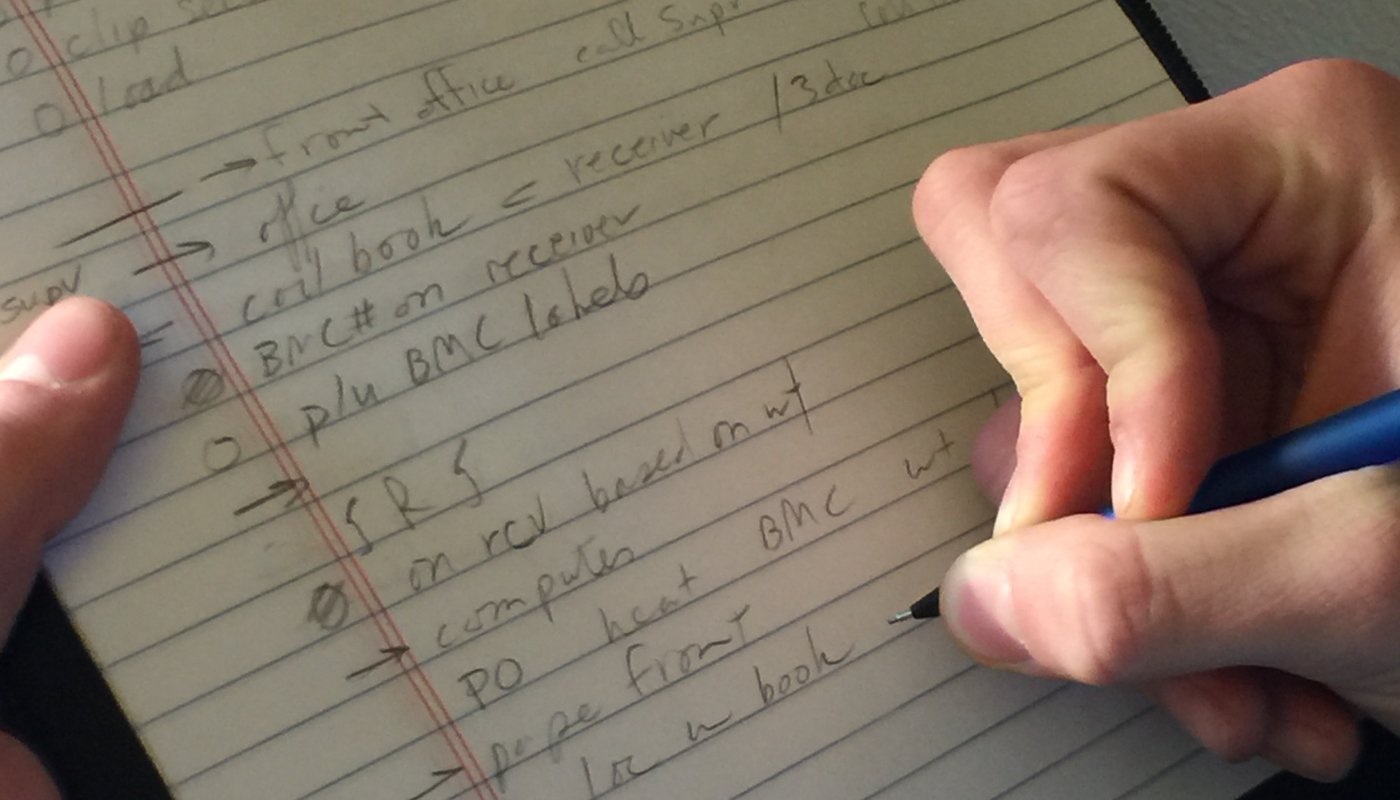

Use mapping shorthand

. The mapping symbols and conventions provide excellent shorthand for recording the data. Jot down a symbol and a few words to explain the activity and go on to the next step. If the task is repetitive, watch several iterations to validate your work and possibly capture variations and exceptions. Most importantly, get the facts from observation whenever possible - people can usually demonstrate the work faster than they can describe it and demonstration is much closer to reality than words.Remember the Questioning Method

. Stick to identifying WHAT happens at each step and avoid detail of HOW steps are performed. This saves an enormous amount of time.Identify the person (WHO) you are interviewing and the work area location (WHERE). These won’t change until you move on to the next work area. Be methodical - follow and list the steps in order (WHEN each occurs relative to the others). Identify the start point and end point for this piece of the process. (i.e. the process starts with an in basket full of orders after the first mail delivery around 8:30 each morning; Each order is entered into the System then set aside for filing.) Start with the activity that triggers the work (orders placed in the ‘in’ basket) then watch the employee process the work.

Ask the employee to SHOW you what they do…fill out the form, review the order, update the database, send the email, make the copy, print the report… whatever they do. Note WHAT is done at each step and get an estimate of the amount of time associated with each delay and any time-consuming steps (Identifying how long a step takes tells us WHEN we get to the next step).

Avoid getting into detail of HOW each step is performed -- answers to the other questions provide us with enough detail to provide proper focus on the step for analysis of the process. Finally, don’t ask WHY. WHY is evaluative and causes people to become defensive. It isn’t necessary to know why at this point. Save WHY for analysis when it becomes the most important question.

A note on the level of detail to look for. A few guidelines can help you get a feel for how much detail to capture. When the symbol changes, capture it. When the source changes, capture it. The handling symbol occurs most often on most charts. There are usually handling operations before and after transports, before and after delays, and before and after sets of value-added symbols and inspections. Digging into the level of detail addresses the question HOW? If you focus on WHAT is happening and not on the details of HOW it is done, the data collection will be easier and quicker, and your chart will be easier to work with.

With the facts in hand, we can prepare a process map. Before we get to that, ponder this. If our goal is to create a new, better process, is it really important that we to talk to the employees to find out what we are doing now? This will be the focus of next month’s paper.

Ben B Graham is President of The Ben Graham Corporation and author of the books 'The Process Improvement Project Guide' and ‘Detail Process Charting: Speaking the Language of Process’. His company pioneered the field of business process improvement, and has provided process improvement consulting, coaching and training services to organizations across North America since 1953. Ben has worked with many organizations to build libraries of business process maps and develop effective, process-focused, continuous improvement programs. His organization publishes Graham Process Mapping Software, which is designed specifically for preparing detail process maps. More information about the software is available at http://www.processchart.com

Buy Graham Process Mapping Software